Mobile:

+86 188 3826 3570WhatsApp:

+86 188 3826 3570Email:

marketing@sogomachine.com

Garri screening machine is a special screening machine with high precision and high efficiency. The sieve plate can continuously separate particles and powder materials of different sizes in Garri through sieves of different meshes, so as to meet various requirements.

The rotary vibrating screen is a kind of high-precision fine powder screening machine. The rotary vibrating screen uses a vertical motor as the excitation source. Eccentric weights are installed at the upper and lower ends of the motor to convert the motor's rotational motion into horizontal, vertical, Tilted three-dimensional movement, and then pass this movement to the screen surface. Adjusting the phase angle of the upper and lower ends can change the movement track of the material on the screen surface

Rotary vibrating screens can be divided into one-layer, two-layer, three-layer, four-layer, five-layer, and 6-layer type rotary vibrating screens, and different layer types of rotary vibrating screens can be selected according to the specific needs of screening materials. The rotary vibrating screen can also be customized into a gate type rotary vibrating screen and an edge type rotary vibrating screen according to different requirements, and the materials are mostly stainless steel and carbon steel. Our company can design and manufacture screen machines with special models and specifications according to the needs of users.

1. Ultra-high structural strength, effectively reducing vibration and noise, and significantly improving the service life of the machine.

2. The base is stable and does not jump, which significantly improves the excitation efficiency, and the spring counterweight bracket is thickened.

3. The surface is smooth and clean, which can effectively avoid the problem of deep penetration of the screw hole of the opening screen bucket. The material is discharged quickly, easy to clean, and does not block.

4. The surface is treated with zinc to ensure smooth surface, not easy to rust, uniform pitch and better elasticity.

5. The whole body adopts S304 stainless steel shell.

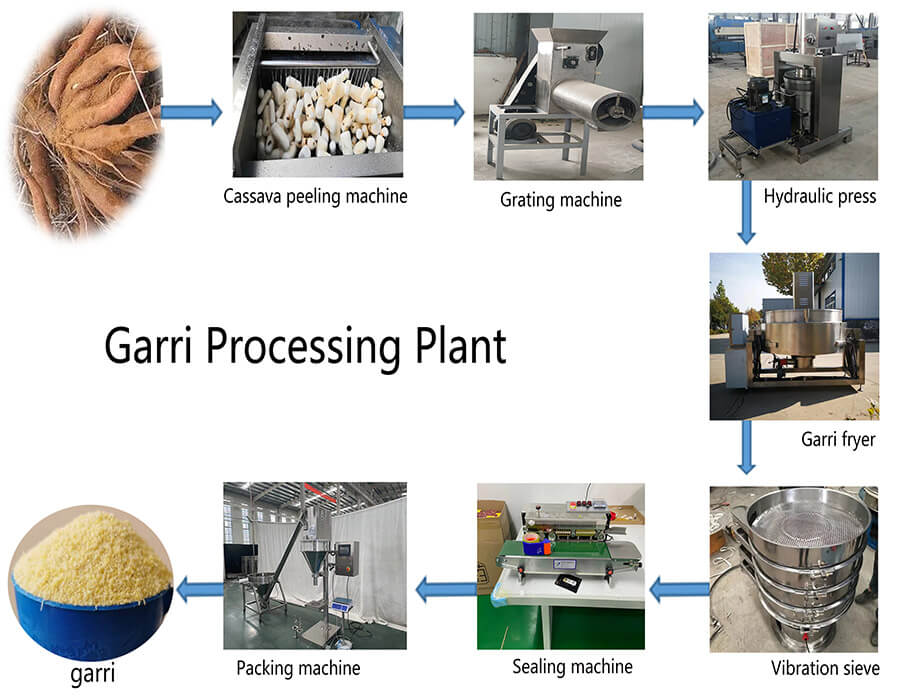

Garri is an important processed product of cassava processing and is very popular among people in African countries. Garri processing is generally divided into cleaning, peeling, grinding, dehydration, frying, sieving and packaging. The equipment required for cassava processing is divided into: dry sieving, paddle cleaning machine, cassava peeling machine, cassava shredder, hydraulic press , frying machine, vibrating screen and packing machine. With modern Garri processing equipment, you can save labor costs and increase Garri production efficiency for higher profits.