Mobile:

+86 188 3826 3570WhatsApp:

+86 188 3826 3570Email:

marketing@sogomachine.com

The cleaning process of cassava starch equipment will use dry sieve and paddle cleaning machine, which is divided into dry cleaning and water washing to remove impurities according to the principle. The dry sieve used in dry cleaning uses the friction and collision between raw materials and between raw materials and equipment to peel off large stones and gravel to achieve the effect of removing impurities.

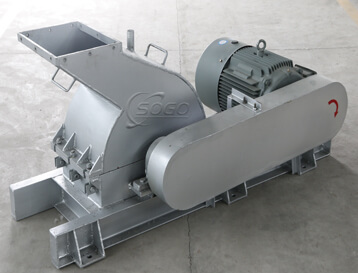

The purpose of crushing is to break the structural organization of cassava and free the bound starch in the root. cassava starch equipment is equipped with a segment cutter and a filing machine in the crushing stage. The "pre-crushing + filing" design improves the crushing rate of raw materials and greatly improves the degree of starch extraction.

Because the fiber cost in cassava starch is high, the cassava starch equipment configured by Jinrui adopts secondary screening. The centrifugal sieve and the fine slag sieve are designed with centrifugal sedimentation raw materials, and the centrifugal difference is used to separate starch and fiber components, and the starch content of the obtained residue is less than 0.2%.

Purification is to separate and process components such as protein, fine fiber, and cell fluid in starch milk to improve the purity of starch milk. The professional starch cyclone group for purification of tapioca starch equipment uses the different centrifugal force of each component to settle and separate to achieve the purification effect.

Starch milk cannot be directly dried in the air dryer, and dehydration treatment is required. The common dehydration equipment for sweet potato starch is equipped with a vacuum dehydrator, which uses vacuum suction filter design, so that the starch milk is slurried on the filter cloth, and the water will be removed through the filter cloth to obtain wet starch with a water content of about 40%, which is in line with the requirements of starch drying. condition.

Drying is to better preserve cassava starch, and the airflow dryer uses the heat transfer between objects to realize the drying function. The hot air is passed into the air dryer, and the starch will rise with the hot air. During the rising process, the hot air will take away the excess starch moisture, and then use the cyclone recovery device to collect the dry starch.