Mobile:

+86 188 3826 3570WhatsApp:

+86 188 3826 3570Email:

marketing@sogomachine.com

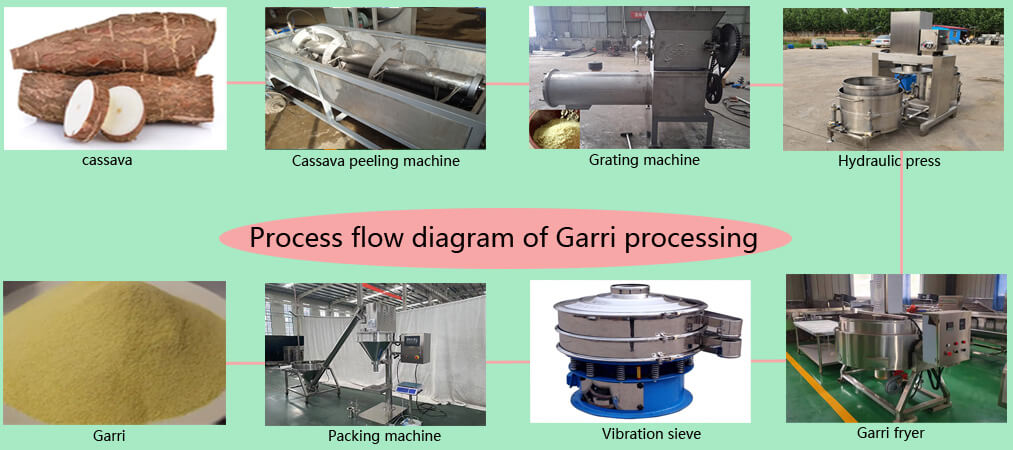

The cassava peeling machine removes the outer skin of cassava, which can ensure product quality and taste. The peeling machine manufactured by SOGO is energy-saving and has a high degree of automation, which can greatly save labor costs and improve production efficiency.

When the machine is running, put the washed and peeled cassava into the grinder. With the high-speed operation of the equipment, the cassava will become cassava puree, and then wait for fermentation.

First put the crushed cassava into the bag, and then put the bag into the hydraulic dehydrator. The dehydrator adopts the principle of hydraulic dehydration. When the equipment is running, the water in the starch emulsion is directly squeezed out.

First preheat the frying pan. After the temperature reaches the specified range, pour the dehydrated Garri into the frying pan, and then start to stir fry the Garri. The frying pan made by Sogo Company is fully automatic and does not require many personnel operate.

Put the dried Garri into the vibrating sieve for sieving. The vibrating sieving is divided into three layers. Screens with different particle sizes can be customized according to needs. The screens are easy to replace and easy to operate.

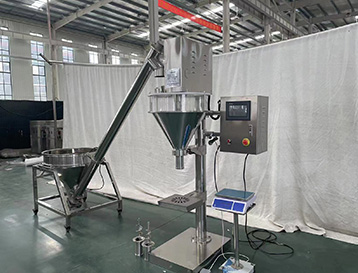

Packaging is the last process of Garri production. After the Garri is processed, the Garri is packaged by a fully automatic packaging machine for easy preservation and sale.