Mobile:

+86 188 3826 3570WhatsApp:

+86 188 3826 3570Email:

marketing@sogomachine.com

Use group of stainless steel brushing,rotate to remove inner and out peel,use variable frequency motor automation take out,high efficient and stable,save worker and time.

Cassava peeling machine, also known as cassava peeling machine, is widely used in garill production line. During the cassava peeling process, the skin part of cassava is removed, which helps to improve the taste and quality of cassava processed products.

The main parts has stainless steel out shell,stainless steel roller,screw propeller,stainless steel roller put on arc state bottom,material input by one side at the stainless steel roller rotary friction to remove the our side peel.Screw propeller push out,the peel will fill down in the between gap,screw propeller use variable frequency motor to control the working speed.

| Type | Outer Size(mm) | Brush number | Production | Speed | Power(kw) |

| SG-6 | 4000*820*1500 | 6 | 2-3t/h |

Infinitely variable speeds |

3.7 |

| SG-10 | 4000*1250*1500 | 10 | 4-5t/h | Infinitely variable speeds | 6.2 |

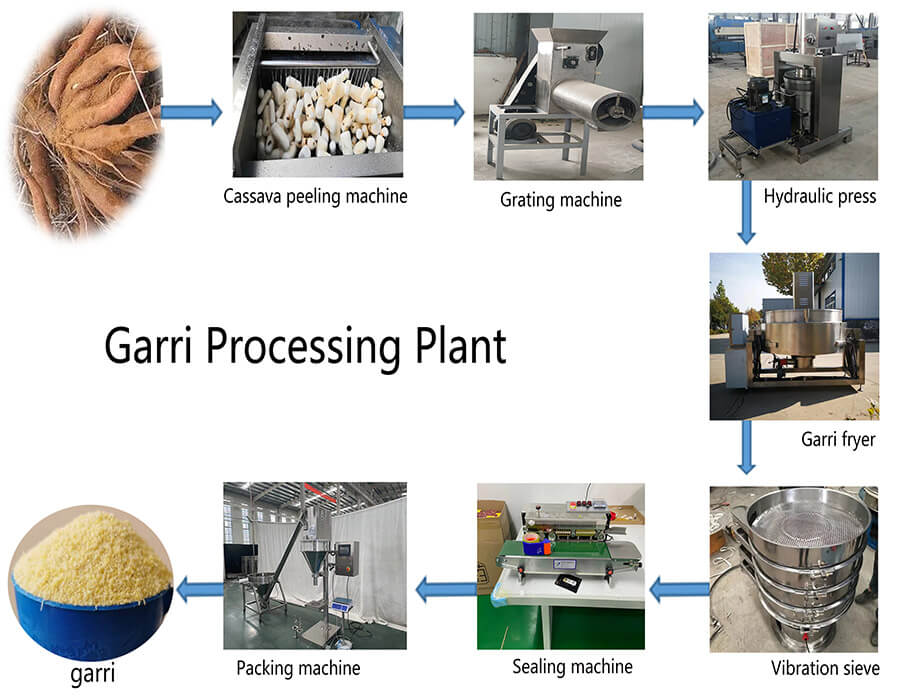

Garri is an important processed product of cassava processing and is very popular among people in African countries. Garri processing is generally divided into cleaning, peeling, grinding, dehydration, frying, sieving and packaging. The equipment required for cassava processing is divided into: dry sieving, paddle cleaning machine, cassava peeling machine, cassava shredder, hydraulic press , frying machine, vibrating screen and packing machine. With modern Garri processing equipment, you can save labor costs and increase Garri production efficiency for higher profits.